- EFFICIENT WEIGHING SOLUTIONS FROM THE MANUFACTURER

sku:

EVEREST(0,5×0,5)D-E

category: PRODUCTS

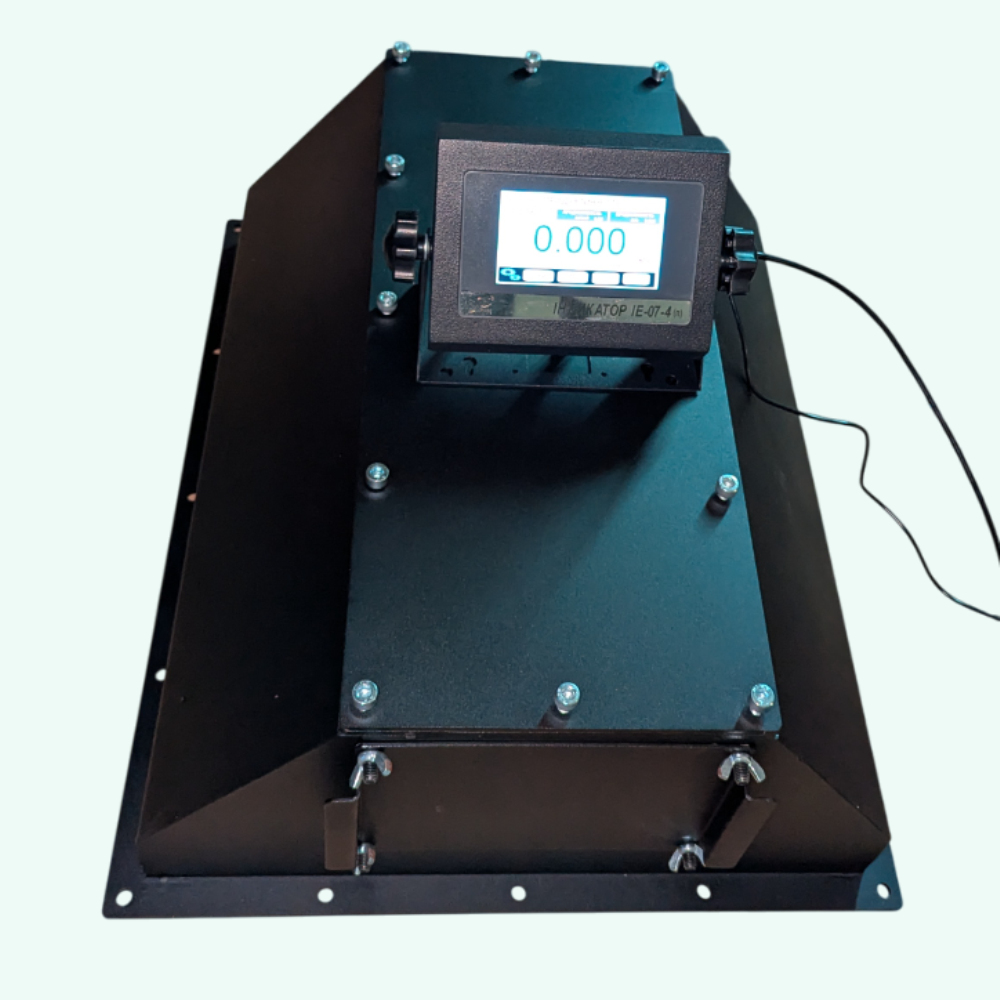

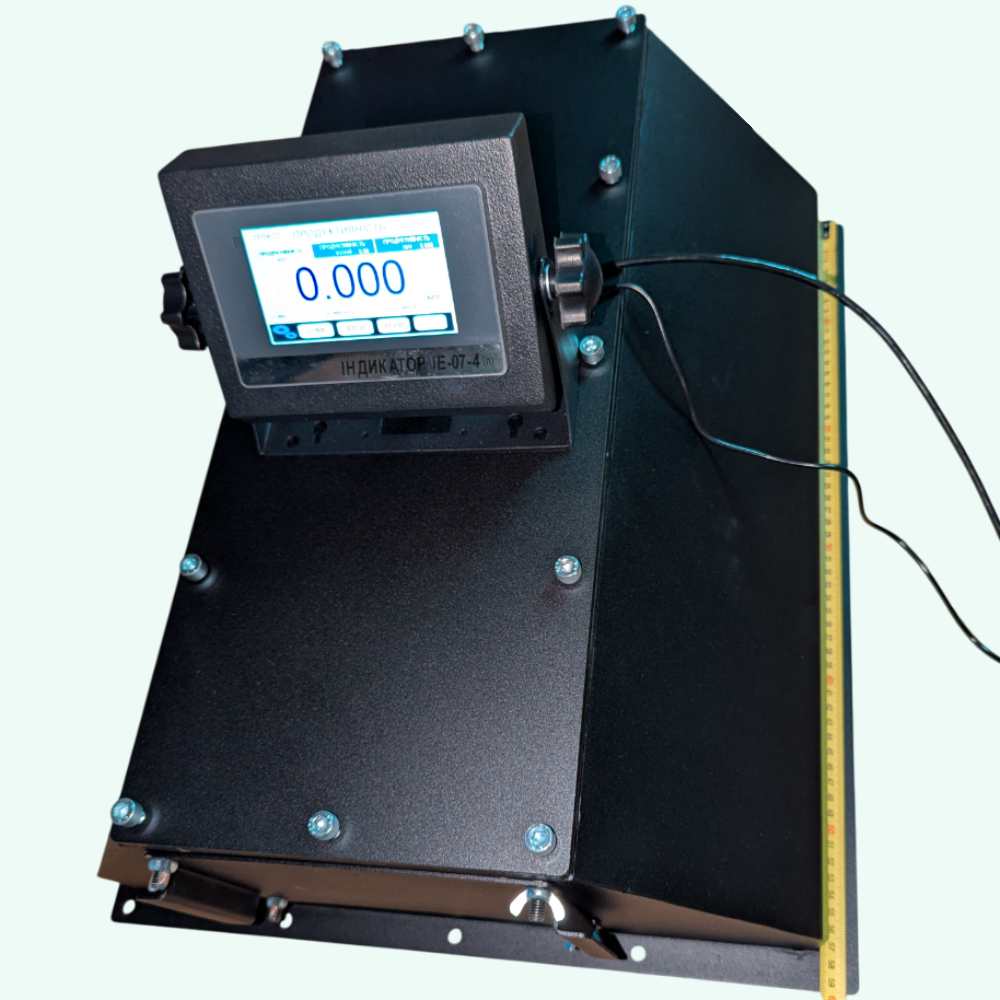

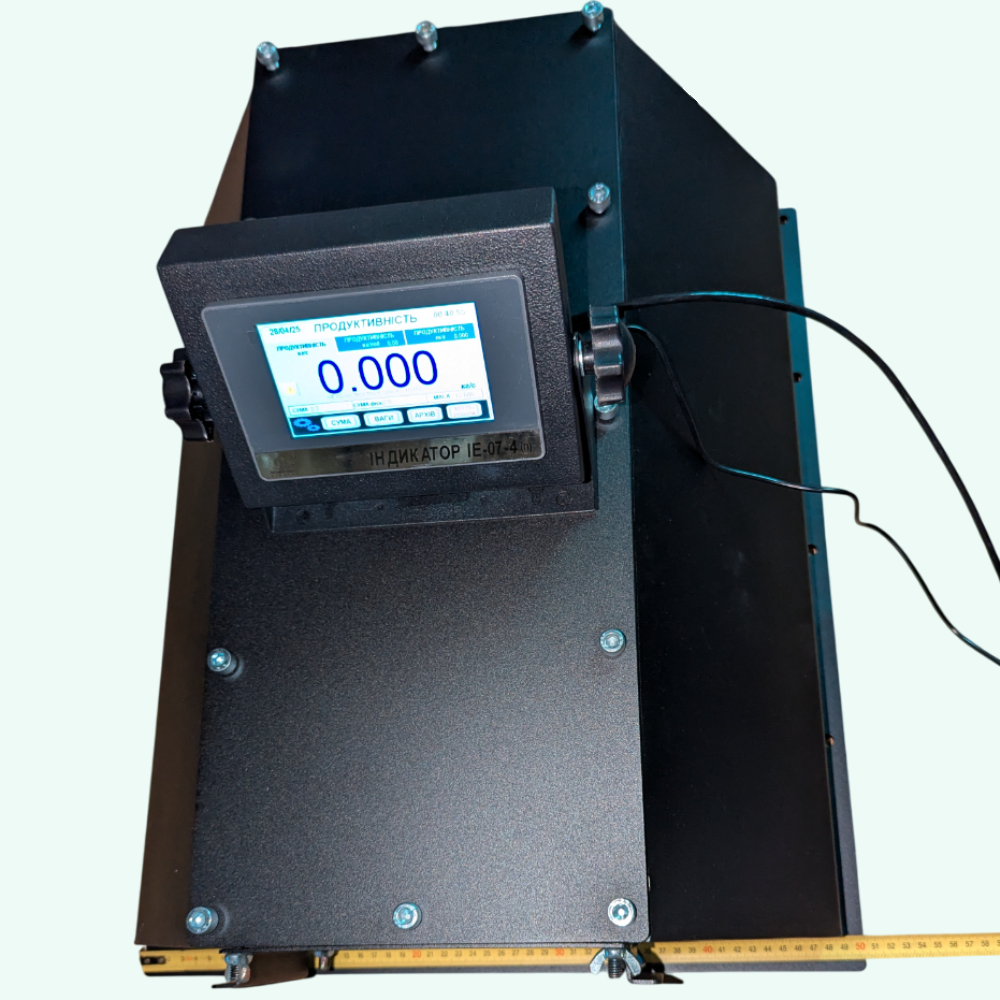

Mass flow meter of dry solid bulk materials EVEREST (0.5×0.5)D

86000 грн Original price was: 86000 грн.77400 грнCurrent price is: 77400 грн.

EVEREST (0,5×0,5)D mass flow meter of our production – flow scales for weighing bulk materials (grain, granular materials, sand, etc.) in a flow.

Quantity

We offer you the EVEREST (0,5×0,5)D mass flow meter of our production. These are flow scales for weighing bulk materials (grain, granular materials, sand, etc.) in a flow.

High weighing accuracy

The weighing error can be within ±1% provided the material to be weighed has homogeneous density, is free-flowing, does not stick or stick to the weighing part and passes through the scales with constant speed by gravity itself without additional acceleration. Also, the scales must be positioned horizontally and be under minimal exposure to vibration, air currents and the like. Otherwise, the error may be greater than the specified values.

Principle of operation of the mass flow meter for weighing bulk solids in flow

The principle of operation of the mass flow meter for weighing bulk solids in flow is that the flow of bulk solids passing through the weighing part is continuously weighed by the load cell. The electrical signal from the load cell, which is proportional to the amount of flow, is transmitted to the weighing terminal (controller) and is shown on the display as the total mass of the material or flow rate. The scales can also transmit information to external devices via an RS232 communication interface. The EVEREST Mass Flow Meter can output control signals (optional) to a frequency controlled feeder or belt conveyor drive and thus regulate the flow rate and quantity of bulk material. In this way the flow scales can be easily integrated into various production processes in elevators, feed mills, concrete mixing plants, etc.

Features of the EVEREST (0,5×0,5)D mass flow meter

With its small overall dimensions the EVEREST Mass Flow Meter can be built into any existing process line.

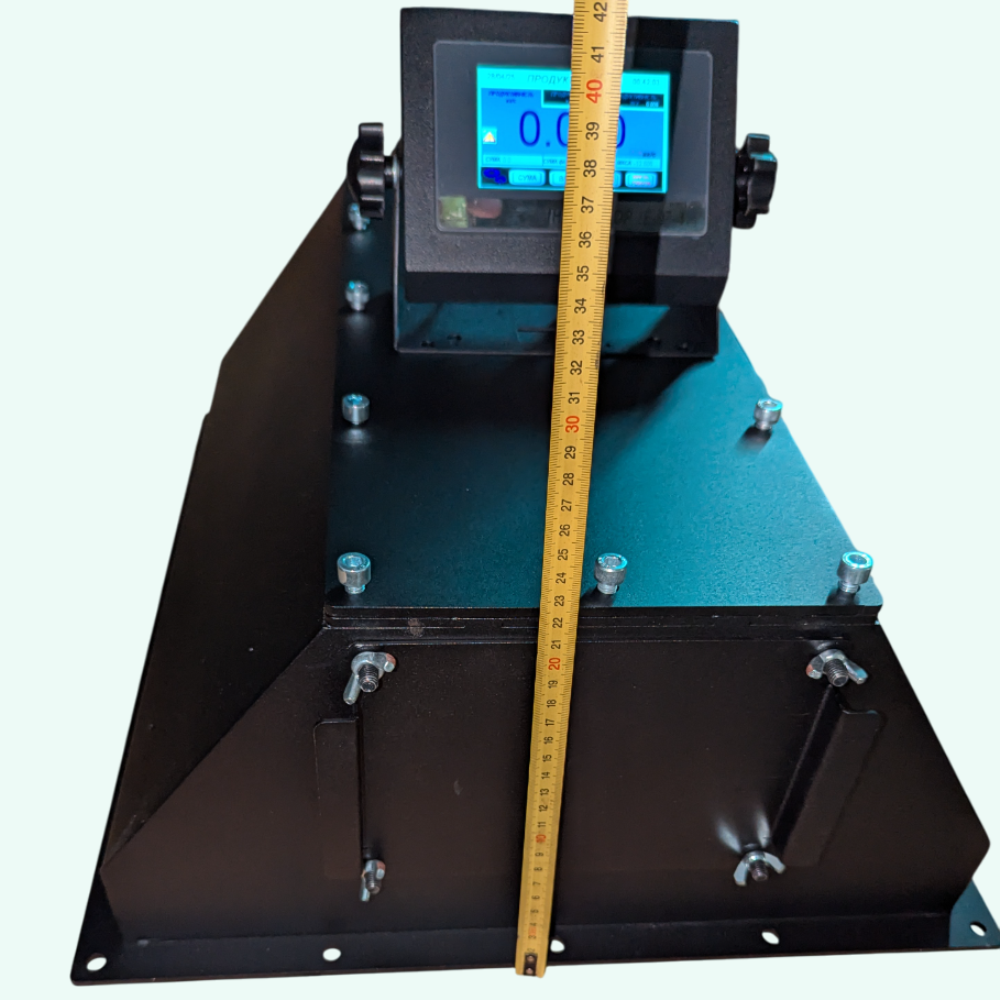

The mounting flange, which comes with the scales, significantly simplifies and speeds up the installation process.

The scales are highly reliable and maintainable. There are no moving parts.

Easy and simple access to the internal components allows quick and trouble-free maintenance.

Technical characteristics of the mass flowmeter

– Flow capacity is limited by inlet opening 500×160 mm, up to approx. 150 t/h

– Overall dimensions, L×Wh×H 600×510×230 mm

– Ambient operating temperature range:

for the weighing part -30 to +50 °C

for the weighing terminal -10 to +40 °C

– Degree of protection of scales terminal IP44

– Power supply voltage 220 V and frequency 50±1 Hz

Delivery set of the mass flow meter EVEREST (0,5×0,5)D:

- Weighing part.

- Weighing terminal (indicator).

- Mounting flange (plate with holes).

- Tensometric cable 3 m, from the weighing platforms to the weight terminal. If necessary, we can complete the scales with a longer cable length.

- User manual in electronic form.

Lead time – up to 15 working days.

Warranty for flowmeter – 12 months.

To connect and configure the mass flowmeter, qualified specialists are not required, any of our clients is able to connect and configure the scales on their own and with the help of our recommendations. To configure the metrological characteristics of the scales you will need to perform a few test weighings of portions of material of known mass.

Additional options: analog or digital output, multimedia display with process visualization, etc. – the price is negotiable.

If you need more information, please contact us.

Related products

-

Sale!

Truck scales 80 tons 18 m MONOLIT with digital load cells

510000 грнOriginal price was: 510000 грн.459000 грнCurrent price is: 459000 грн. Add to cart -

Sale!

Weighing in motion truck axle scales EVEREST 20t (0,6×0,9)D

235000 грнOriginal price was: 235000 грн.210000 грнCurrent price is: 210000 грн. Add to cart